Since its establishment in 1969, Jiangsu Wanda Special Bearing Co., Ltd (Former Rugao Wanda Special Bearing Company) has been a high‑tech enterprise dedicated to researching and producing special bearings. With advanced precision experimental equipment, top‑notch production lines and a provincial technology centre plus a provincial special bearing engineering technology research centre, we focus on innovating new products, designing bearing functions, discussing industrial vehicle bearings and even drafting the relevant technical standards.

1. What Are Forklift Bearings and Why They Matter

1.1 Definition and Function

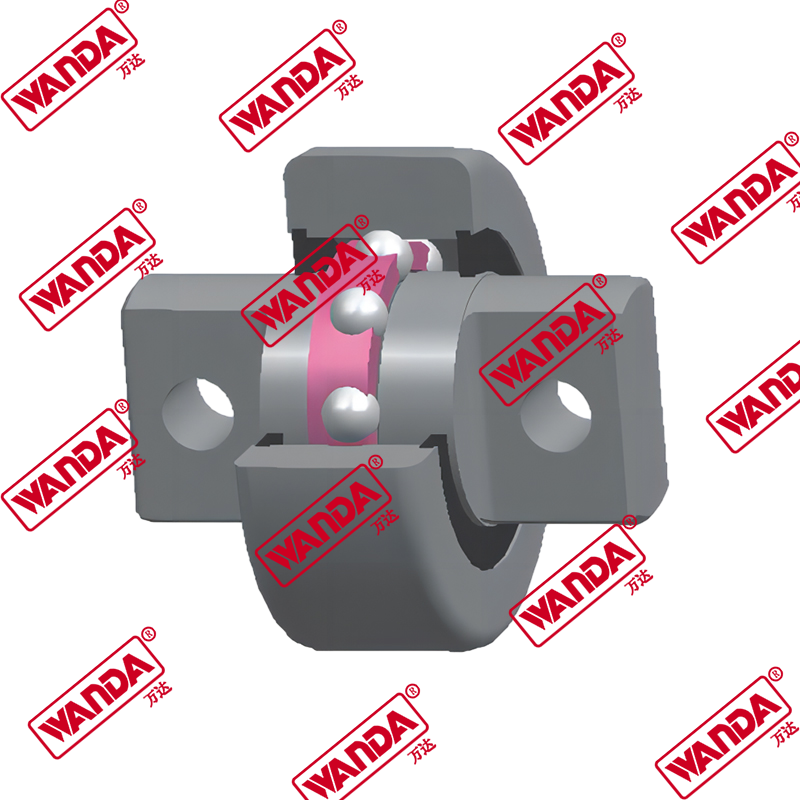

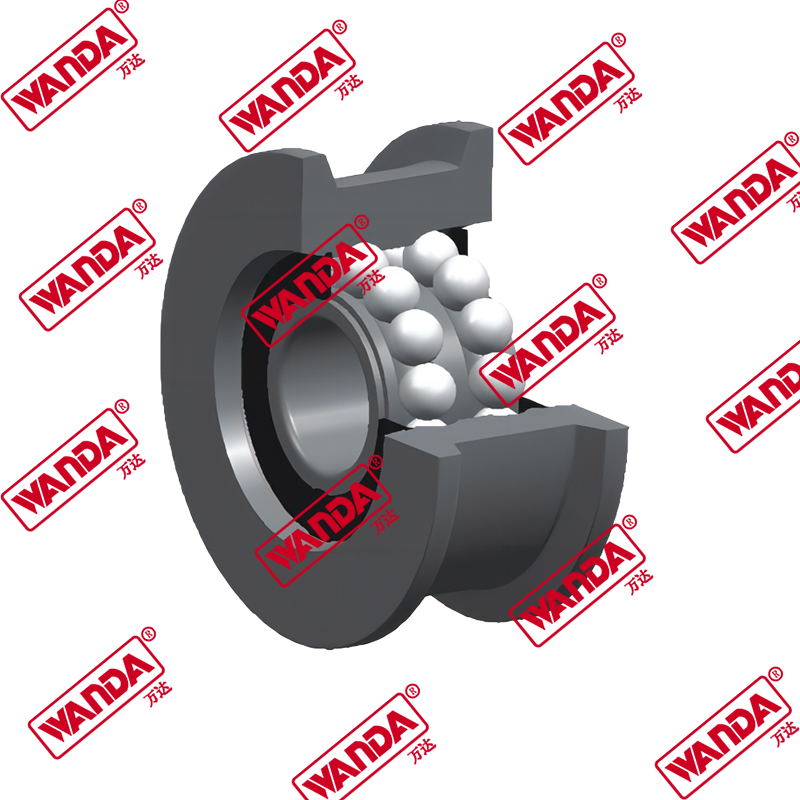

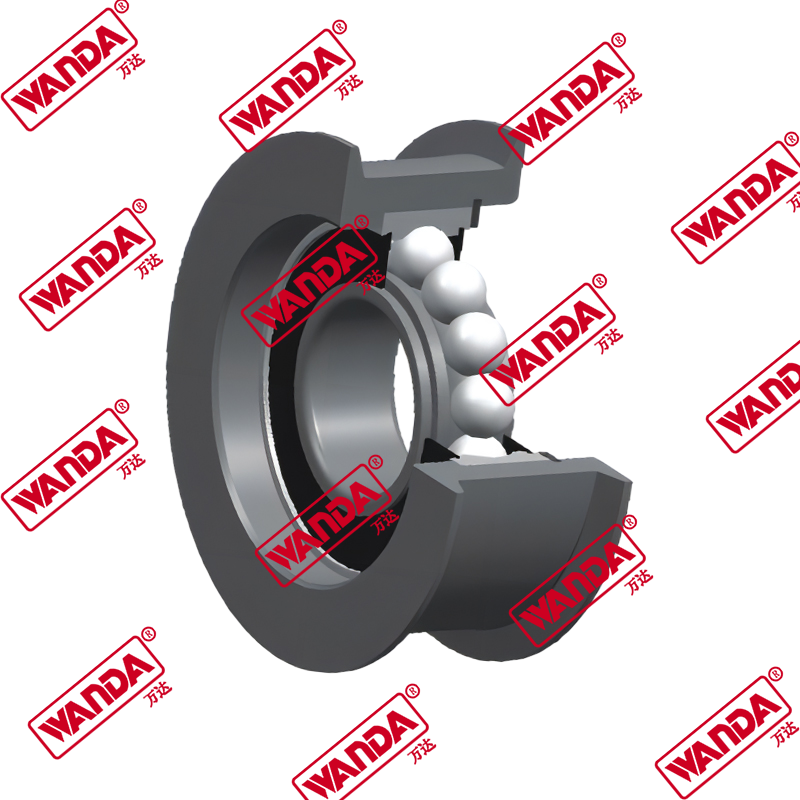

- Forklift Bearings are specialized bearings used in forklifts’ mast, carriage or wheel assemblies to support radial and axial loads, guide movement and enhance stability.

- They play a crucial role in ensuring smooth lifting, lowering and maneuvering of material handling equipment under demanding conditions.

1.2 Key Performance Requirements

- High load‑carrying capacity to handle heavy forks and loads.

- Resistance to misalignment, shock, vibration and contamination — typical in forklift operations.

- Minimal friction and long service life to reduce downtime and maintenance cost.

2. Understanding Types and Applications

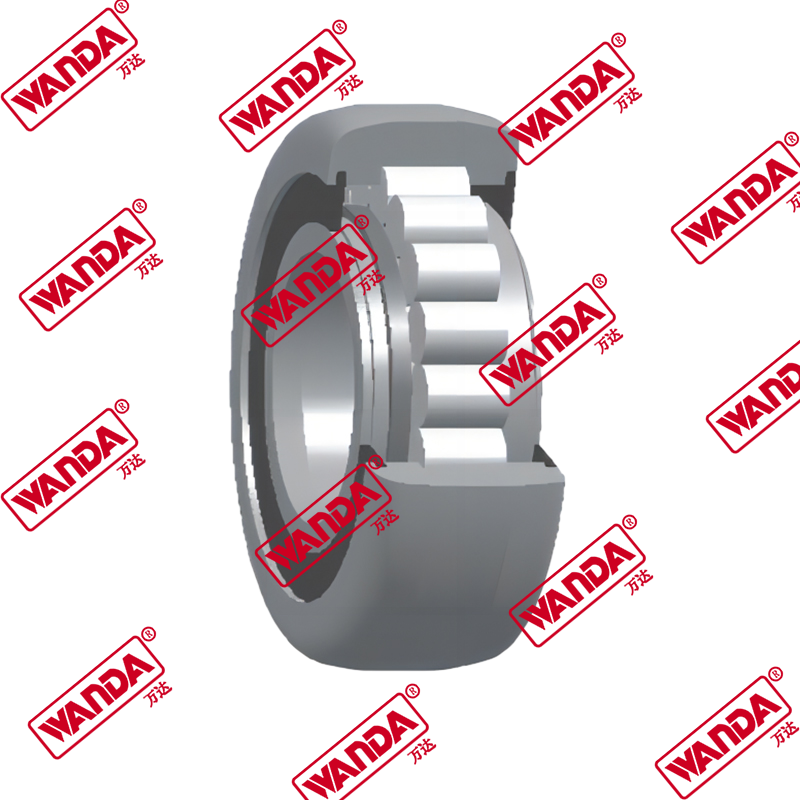

2.1 Guide Bearings vs Side Thrust Rollers

- Guide bearings primarily support vertical movement of the mast rail.

- Side thrust rollers manage lateral forces when the mast tilts or when loads shift.

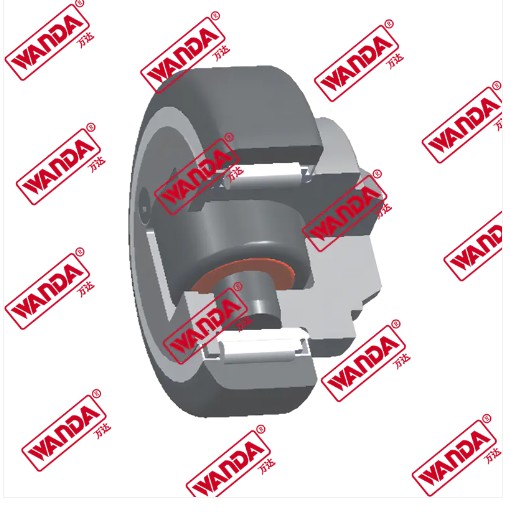

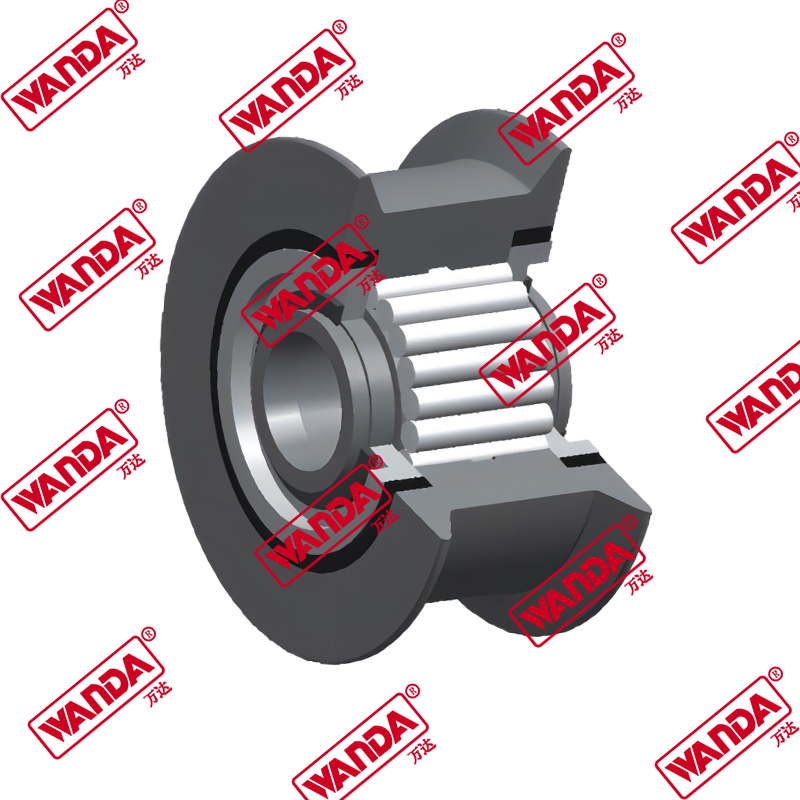

2.2 Combined Solutions for Mast Assemblies (relating to mast roller bearings for forklift trucks )

A combined bearing solution integrates both radial and thrust capacities, meaning one assembly handles both vertical and lateral loads. Below is a comparison:

| Feature | Separate Guide Thrust Bearings | Combined Mast Roller Bearings |

| Number of components | Two or more distinct units | One integrated assembly |

| Installation complexity | Higher (alignment of multiple parts) | Lower (single unit alignment) |

| Space requirement | More space needed | Reduced footprint |

| Cost risk | Multiple failure points | Single failure point but simpler maintenance |

---

3. How to Select the Right Bearings for Heavy‑Duty Use

3.1 Matching Load and Duty (relating to forklift bearings for heavy duty forks )

- Estimate the maximum radial and axial load expected in your forklift application.

- Heavy‑duty forks and extended duty cycles demand bearings with high dynamic and static load ratings.

- Consider environmental conditions: dust, moisture, temperature — they all affect bearing selection.

3.2 Material, Seal and Maintenance Factors

- Choose deep‑hardened steel or special alloy to resist impact and edge loading.

- Advanced seals or labyrinth seals help exclude contamination and prolong life.

- Maintenance intervals and lubrication compatibility are critical — selecting a bearing with easier serviceability can save downtime.

4. Maintenance & Lubrication Best Practices

4.1 Recognising the signs of worn forklift mast bearings

- Unusual noise (grinding, clicking) during mast movement.

- Inefficient lift or lowering, mast wobble or uneven carriage travel.

- Excessive play or lateral movement in the mast assembly — early indicators of bearing wear.

4.2 Creating a lubrication schedule for forklift bearings

A planned lubrication schedule extends bearing life and ensures consistent performance. Below is a comparative overview:

| Operational Condition | Recommended Lubricant Type | Application Frequency |

| Standard indoor use | Lithium‑complex grease | Every X hours (as per manufacturer) |

| High temperature or heavy loading | Synthetic high‑temperature grease | More frequent than standard |

| Contaminated or wet environment | Calcium‑sulfonate complex or sealed lubricant | Standard intervals but monitor wear closely |

- Always clean bearing housings and mating surfaces before re‑lubrication.

- Over‑greasing can cause heat build‑up; under‑greasing accelerates wear.

5. Implementing a Bearing Strategy for Industrial Vehicles

5.1 Planning Proactive Replacement

- Track operating hours, load cycles and bearing condition reports.

- Replace bearings during scheduled maintenance rather than reactive failure to avoid costly downtime.

- Keep proper inventory of critical bearing sizes and specifications.

5.2 Selecting forklift bearings for industrial vehicles : a decision‑matrix overview

- List operational parameters: load, environment, duty cycle.

- Match these to bearing ratings: dynamic/static load, material, sealing class.

- Choose a supplier (such as our company) with advanced lab and production capacity to ensure consistency and long life.

FAQ

- Q1: How often should forklift bearings be inspected?

A: It depends on usage, but typically every 250–500 hours of operation or sooner in heavy‑duty or harsh environments. - Q2: Can I mix different brands or types of bearings in the same mast assembly?

A: It’s not recommended because mismatched bearing types may lead to uneven load distribution and premature failure. - Q3: What’s the major difference between standard bearings and those designed for forklift mast use?

A: Forklift mast bearings are engineered for extreme radial and axial loads, edge loading and misalignment — far more demanding than typical bearings. - Q4: What are the signs that I need to replace forklift bearings immediately?

A: Persistent unusual noise, abrupt increase in mast play, slow or jerky movement or visible damage to bearing raceways. - Q5: Does using a higher grade lubricant always extend bearing life significantly?

A: Not always. It must match the operating conditions. Using an advanced grease in a low‑duty, low‑temperature environment may not yield proportional benefits and could reduce grease life.